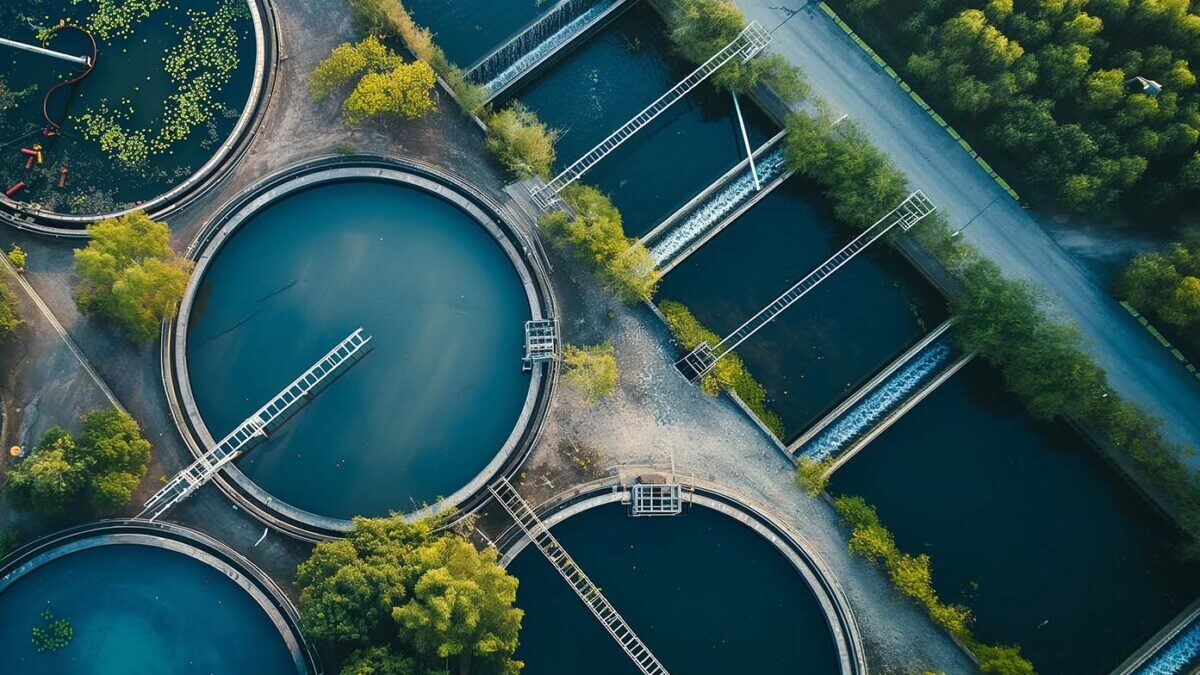

The aging infrastructure of water and wastewater systems presents a significant challenge to water supply and wastewater treatment plants. Leaks, corrosion, and mechanical failures can result in costly downtime, water loss, and environmental contamination.

Chesterton offers a comprehensive range of advanced sealing and engineering solutions designed to extend the lifespan of critical infrastructure components. From high-performance mechanical seals and packing to corrosion-resistant coatings or industrial lubricants, Chesterton® products help prevent leaks, reduce maintenance requirements, and ensure the reliable operation of water and wastewater systems for years to come.

Sealing Reliability

Chesterton® mechanical seals and packing have proven to lower maintenance costs and deliver extended uptime in potable and wastewater applications. Many products are designed to extend the life of worn equipment and meet many international potable water requirements.

Find out more:

- Chesterton Mechanical Seals: Indispensable in the Water and Wastewater Sector

- Boosting Pump Performance and Increasing Pump Availability Using Chesterton DualPac 2212 Packing

Proven success – Featured Case Studies

- MSD- Chesterton 170 Improved Reliablility Without the Need for Flush (Chesterton 170 Slurry Single Cartridge Seal)

- MSD- Chesterton 442C Cartridge Split Seals Switch Results in Easy Installation (Chesterton 442C)

- MSD- Wastewater Plant Damatically Reduces Seal Installation Time with Split Seals (Chesterton 442C)

Equipment Monitoring

The Chesterton Connect™ system is a condition-based maintenance tool designed to monitor the health of critical equipment. Avoid unplanned downtime, reduce maintenance costs, and protect your assets by remotely monitoring equipment health 24/7/365.

Find out more:

- The Chesterton Connect IIoT Solution Significantly Increases the Reliability of Pumps and Rotating Equipment

Proven success – Featured Case Studies

- Connect – Chesterton Connect Sensor Reduces Submersible Pump Damage at Lift Station (Chesterton Connect Sensor and Cloud)

- Connect – Chesterton Connect Sensor Helps to Determine the Cause of Costly Seal Failures (Chesterton Connect Sensor or System)

- Connect – Efficient 24/7 Monitoring of Pump Stations with Chesterton Connect (Chesterton Connect)

Industrial Coatings

Aging infrastructure is the #1 challenge in the water and wastewater industry. Our advanced coatings make it possible to repair older metal and concrete assets, minimizing downtime and expense. Applying ARC Industrial Coatings on new and older equipment can help maximize energy efficiency, while meeting many international potable water requirements.

Find out more:

Proven success – Featured Case Studies

- Coatings – Clarifier Protected with Chesterton ARC S1PW (ARC S1PW, ARC 858)

- Coatings – Wastewater Gravity Thickener Overflow Pump (ARC 855, ARC 858)

- Coatings – Sand Filter Vessel (ARC S1PW)

Performance Lubricants

Chesterton industrial lubricants and greases are specifically engineered to protect bearings in harsh conditions, including load, vibration, water, chemical vapors, and corrosion.

Quiet Bearing Technology (QBT™ ) combines exceptional water washout and corrosion resistance with extreme pressure and temperature resistance to increase bearing life and equipment reliability.

Find out more:

Proven success – Featured Case Studies

- IL / MRO – Water Treatment Plant, Potable Water (630SXCF)

- IL / MRO – University HVAC Cooling Tower (Lubri-Cup EM/615 HTG)

- IL / MRO – Digester Agitator (615 HTG, Lubricup EM, 30KC)

Experience the Difference with Chesterton

Choose Chesterton as your trusted partner and gain a competitive edge. We are ready to support you effectively with our industry-leading products, skilled expertise, and strong commitment to customer satisfaction.