In the world of the water and wastewater industry, lubricants are a critical and essential component for the smooth operation of mechanical equipment. These often overlooked oils and greases play a crucial role in the reliability and efficiency of mechanical components in water and wastewater treatment plants. It is important to recognize that not all lubricants are the same and that significant benefits can be achieved using modern high-performance lubricants.

But what exactly are the benefits of these high performance lubricants?

- Reducing friction and wear

In an environment where equipment operates continuously and are often exposed to extreme conditions, minimizing friction and associated wear is critical to equipment longevity. Lubricity and extreme pressure additives help the lubricant reduce friction and prevent wear between the moving parts. High performance lubrication effectively protects moving parts of bearings, chains, valves, motors, gearboxes, etc. which in turn extends equipment life and reduces the need for costly repairs. - Improving efficiency

Efficiency is a key word in any industry, and water and wastewater treatment is no different. High performance modern lubricants with low coefficient of friction help bearings and conveyor chains work more efficiently as less energy is required for operation. This leads to direct cost savings through lower energy costs, while also helping to make plants more environmentally friendly by reducing energy consumption. Remember lowering friction also means reduced wear on the equipment. - Prevention of breakdowns and malfunctions

High performance modern lubricants increase equipment lifetime reducing breakdown and downtime. This increases the operational reliability of the plant and the spend on unplanned maintenance and replacement parts. This is crucial, as breakdowns not only lead to additional costs, but also affect the operation of the entire processing plant. - Protection against corrosion and contamination

In water and wastewater plants equipment is often exposed to water, moisture, chemicals and the environment. These conditions provide a challenge for the lubricants and can result in equipment corrosion, seizure, increased maintenance and replacement parts. Water resistance and corrosion resistant lubrication technology is important to insure equipment reliability. This helps prevent corrosion and seizing of equipment such as threaded assemblies(nuts and bolts). High-quality lubricants reduce the penetration of dirt particles into the mechanics and offer reliable water resistance and corrosion protection.

Advanced lubricant technology from Chesterton: We offer targeted solutions for efficient cost reduction and performance optimization

Chesterton carries an extensive range of industrial lubricants, cleaners, corrosion protection and specialized maintenance products that keep vital machinery running smoothly and efficiently.

Our goal is to use the latest raw material technology with the ultimate goal of reducing our customers’ costs.

By using modern raw materials, we manufacture industrial lubricants with excellent protective properties against corrosion, high and low temperatures, high-pressure loads, heavy abrasive wear and water washout.

Benefits our customers have seen in their plants include:

- Extending equipment service life

- Reduction of premature failure

- Improving the reliability of the systems

- Optimizing the performance of the equipment

- Cost reduction

- Increased productivity

Whether its bearings, motors, agitators, gears, chains, mechanical assemblies – with our advanced modern lubricants and specialty chemical products you can increase the efficiency and lifetime of your equipment and reduce your maintenance and operating costs.

For example, our high-performance, corrosion-inhibiting grease 617(E) HP Grease #2 is the ideal choice for demanding operating conditions. It maintains performance even at extreme pressures and very high or cold operating temperatures. Applications in water-rich environments are no problem, as this high-performance grease has excellent resistance to water washout.

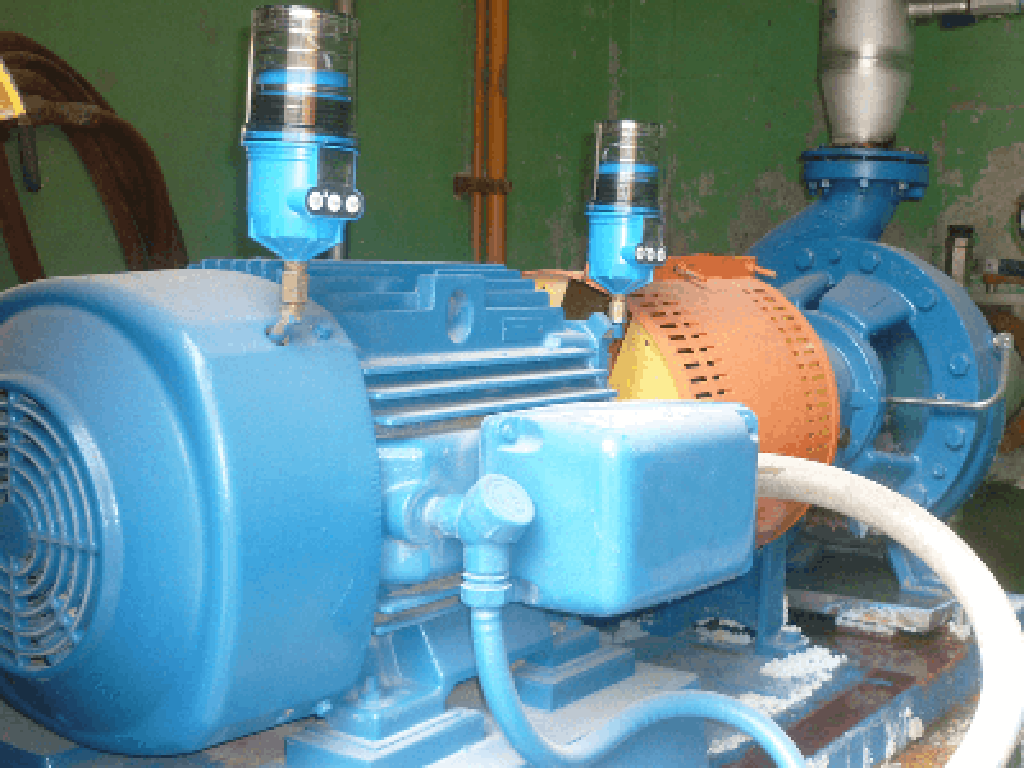

Continuous lubrication with Chesterton LubriCup

The lubricators from Chesterton enable constant lubrication of bearings and chains. Filled with the appropriate Chesterton high-performance grease or oil, the various LubriCup systems provide a processor-controlled, precise delivery of lubricant to the point to be lubricated.

Maintenance work is significantly reduced thanks to automatic lubrication. For areas that are difficult to access, the use of Chesterton LubriCup also means an increase in work safety, as the lubrication points can be safely accessed using a lubrication line.

However, the most important aspect of using our LubriCups is that there is no risk of over- or under-lubrication. Under lubrication can mean the equipment runs dry reducing the lifetime. Over lubrication can result in excessive consumption of lubricants, making it uneconomical and causing lubricant dripping or leakage. These are scenarios that you can effectively avoid with our lubricant dispensers.

Chesterton supports you with an experienced team of competent technicians to find the optimum lubricant solution for your specific requirements.

If you have any questions about lubrication, please contact us via our Ask an Expert platform.

We will gladly assist you with your operating challenges.

You can also make a preliminary selection using our product selector. Our product consultants will gladly assist you in selecting the ideal product for your application.