Power Performance for the Power Industry – Chesterton® ARC SD4i Protects Storage Tanks for Ultra-high Purity Water

In thermal power plants, regardless of the type of fuel used, the need for high-purity demineralized water is essential. This water is critical for producing steam to drive turbines and generate electricity. A reliable supply of demineralized water helps ensure the efficient and safe operation of the plant, as it prevents scaling and corrosion in […]

Read MoreMINING INDUSTRY: Chesterton’s Cutting-Edge Solutions for the Mining Industry!

Increasing Efficiency for Mining Machinery is our Priority Mechanical stress, severe impacts, slurries, dust and dirt, corrosion, and lack of water can significantly reduce the reliability and uptime of mining equipment. Chesterton specialists help mining companies worldwide overcome these challenges with expertise and advanced solutions in sealing, lubrication and protective coatings. Boost your Mining Operation […]

Read MoreWATER and WASTEWATER: Chesterton’s Role in Water and Wastewater Industry – Increase Asset Reliability and Longevity

The aging infrastructure of water and wastewater systems presents a significant challenge to water supply and wastewater treatment plants. Leaks, corrosion, and mechanical failures can result in costly downtime, water loss, and environmental contamination. Chesterton offers a comprehensive range of advanced sealing and engineering solutions designed to extend the lifespan of critical infrastructure components. From […]

Read MoreHYDROPOWER: Solutions that increase reliability and reduce costs – we improve performance in the hydropower industry

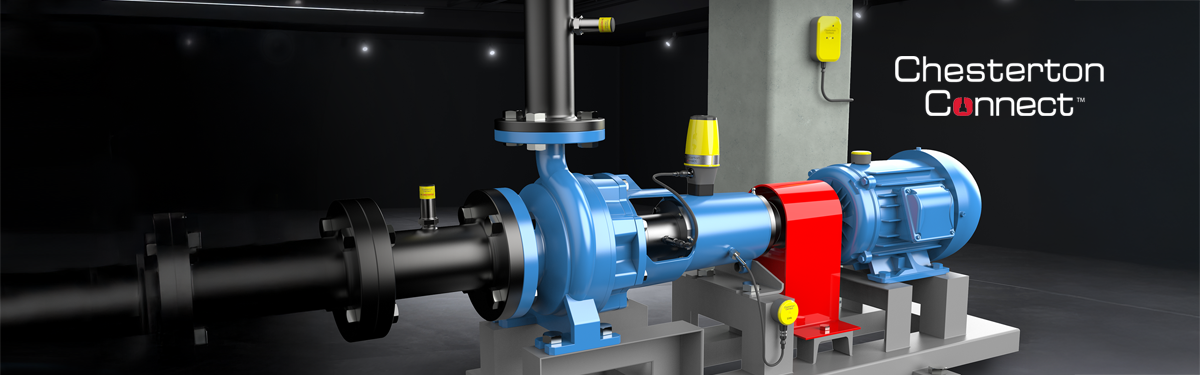

Chesterton is a global manufacturer of industrial fluid sealing systems, industrial coatings, lubricants, and maintenance specialties. Working with hydropower plants around the world, we have gained knowledge and expertise that continue to help us develop unique solutions to address the specific challenges faced by the hydropower industry, including fluid containment, corrosion and wear control, and […]

Read MorePULP and PAPER: Chesterton’s Expertise and Solutions – Meeting the Challenges of Pulp and Paper Production

The pulp and paper industry operates in one of the most demanding environments. Transforming raw materials like wood and waste paper into finished paper products involves multiple stages, each with its own challenges. High temperatures, wet conditions, and the use of mineral and chemical additives all place stress on mechanical equipment. To meet these demands, […]

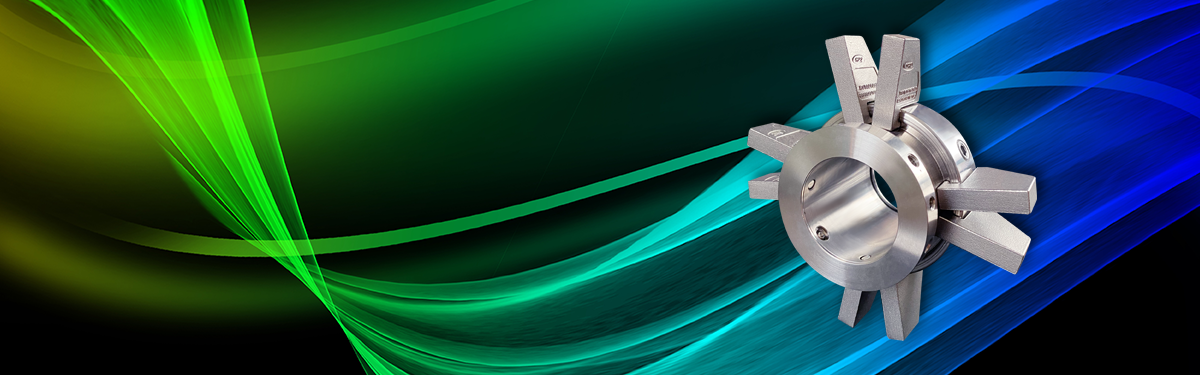

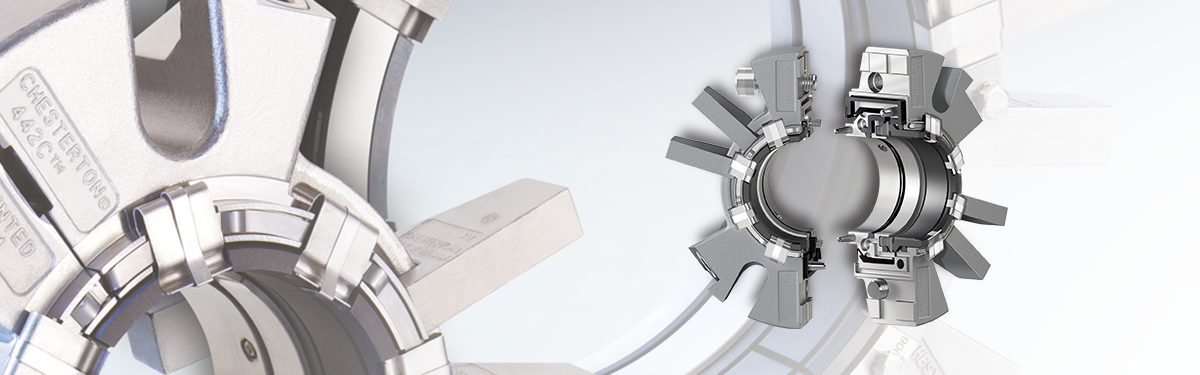

Read MoreChesterton® Mechanical Seals: Game Changer for Profitability in Pulp and Paper Plants

Chesterton is a full-solutions provider for pulp and paper mills and understands energy, efficiency, reduced water consumption and downtime are key cost differentiators in the industry. The pulp and paper industry faces several significant challenges today. These challenges span environmental, economic, technological, and regulatory aspects. Some of the main challenges are the aging infrastructure, cost […]

Read MoreRoll on, Roll on, Roll on – with Chesterton® Advanced Bearing Reliability Programs

Modern paper machines are up to 150 meters long, 10 meters wide and run at speeds of up to 2000 meters per minute. Huge giants, 24/7 in operation, programmed for smooth production without downtime. Outside of the paper machine itself there is a complex process including the wood yard, stock preparation, pulping and paper conversion. […]

Read MoreProduction Efficiency and High Pump Reliability thanks to Innovative Packing Technology

Paper and pulp production is an extremely demanding industry. It is a long way from the processing of raw wood to the production of fine writing paper. In many manufacturing steps, the abrasive raw material is processed with hot water and chemicals. This means that all machine components need to be highly resistant to wear, […]

Read MoreChesterton® High-Performance Industrial Coating Solutions for Corrosion and Abrasion Challenges in the Pulp and Paper Industry

The pulp and paper sector is a demanding industry. From debarking and wood processing to the chemical processing of paper pulp and the manufacture of finished products – the work steps in this field are complex. The production of paper, cardboard and pulp requires many machines, a lot of water and certain chemicals. Plant operators […]

Read More