Chesterton has launched its revolutionary new DualPac® 2212 pump seal.

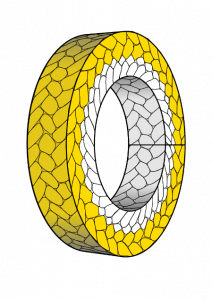

Dualpac® is a unique braiding technology invented and patented by Chesterton that allows the braid manufacturer, for the first time in history, to give the dynamic side of the braid the ideal properties for a dynamic seal, and the static side of the braid the ideal properties for a static seal.

An industrial braid specially designed for demanding applications

Launched two years ago, the first DualPac® version was the Dualpac 2211 pump seal braid – this robust and strong braid was specifically developed for the sealing requirements of severe applications in the mining industry. This braid design has proven to be very effective in extending the usually very short MTBR.

Based on this success, Chesterton’s product development team worked on a new braid to cover a wider range of applications. This research resulted in DualPac® 2212, a new pump seal braid.

A braid with two complementary fibres

The DualPac® 2212 braid incorporates two types of fibres of different materials:

- On the dynamic side, we have a fibre made of meta-aramid. This material has interesting properties such as high heat and burn resistance and avoids damage to the shaft.

- On the static side, i.e. where the braid is in contact with the inner wall of the stuffing box, we have a para-aramid fibre. This material has an excellent mechanical strength and a very good resilience. The resilience of this fibre allows the whole braid to apply a constant pressure on both sides to be sealed (dynamic and static sides), thus extending the interval between gland tightenings and increasing the life of the braid. Due to the design of the braid, the para-aramid fibre is not in contact with the shaft which eliminates the shaft wear usually associated with para-aramid.

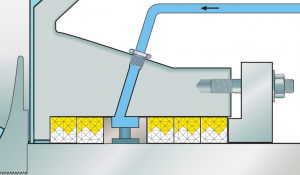

Less maintenance and increased safety

With this braid, users have reduced maintenance time, reduced operating costs and increased plant safety by reducing leakage from flushing water. The braid is recommended for applications where abrasive fluids need to be sealed, such as in the wastewater treatment and drinking water industries, as well as the paper and sugar industries.

Chesterton’s patented Dualpac technology revolutionises the way braids are sealed. With the Dualpac 211 and DualPac 2212 pump seals, it sets a new standard for sealing rotary equipment with braids.

Learn more about braids for water pumps, paper pumps, sludge, agitators, mixers, ask for a demo.