The Mining Industry: A Gritty Challenge

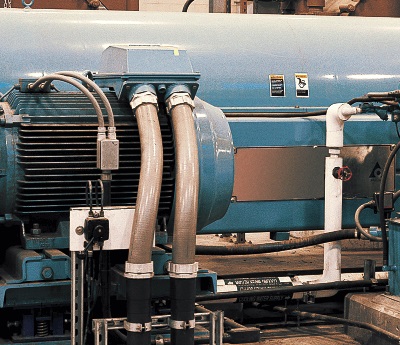

The mining industry is a vital economic sector, driving growth and development globally. However, it is also an environment where equipment reliability is constantly tested by harsh conditions. One of the most persistent challenges in this sector is the maintenance of electric motor bearings—a crucial component in the machinery that powers mining operations.

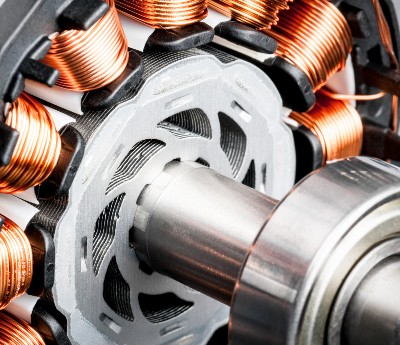

Electric motor bearings are subjected to extreme stress due to heavy loads, high temperatures, and corrosive environments. When these bearings are not properly lubricated, the result can be premature bearing failure, leading to costly downtime and repairs.

The Importance of High-Quality Grease

Choosing the right grease for electric motor bearings is not just essential—it is critical. The wrong type of grease can lead to inadequate lubrication, increased friction, overheating, and ultimately, bearing failure. This is where Chesterton 638 Electric Motor Grease (EMG) comes into play.

Chesterton 638 Electric Motor Grease (EMG)

Designed specifically to combat the challenging conditions that electric motor bearings encounter, Chesterton 638 EMG is a high-performance grease that ensures optimal lubrication under demanding conditions.

This advanced grease is formulated to outperform traditional Polyurea-based greases and older Lithium technology. With its superior resistance to water, corrosion, and high temperatures, Chesterton 638 EMG provides reliable protection to bearings, significantly reducing the risk of failure and extending the life of your motors.

Addressing Electric Motors in Wet & Corrosive Areas

Did you know that up to 75% of energy usage in the mining industry is due to electric motors? Moreover, a significant portion of annual expenses goes towards maintenance and replacement due to bearing and winding failures.

Electric motors operating in wet and corrosive areas are particularly prone to these issues. However, with Chesterton 638 EMG, you can protect your motors from the toughest environmental challenges.

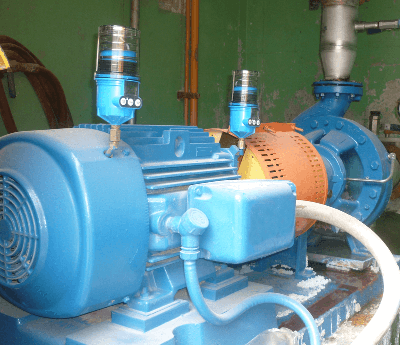

The Power of Automation: Lubri-Cup EM

To further enhance the effectiveness of our solution, we offer the Lubri-Cup EM—an automatic grease dispenser that ensures continuous, precise lubrication. This innovative device eliminates the guesswork from manual lubrication and helps extend the life of your bearings.

The Lubri-Cup EM paired with Chesterton 638 EMG offers a powerful combination that can reduce the annual motor replacement rate in the mining industry, which currently stands at over 15% of installed motors.

In Conclusion: The Chesterton Advantage

By choosing Chesterton solutions, you are not just selecting a product—you are investing in reliability, durability, and efficiency. Our high-performance grease and innovative automatic dispenser provide a comprehensive solution to prevent bearing failures and keep your mining operations running smoothly. Trust Chesterton—because your equipment deserves nothing less.

Talk to us! We will be happy to offer you the optimum lubrication solution. Please ask our Expert Desk for further information.

You can also make a preliminary selection using our product selector. Our product consultants will gladly assist you in selecting the ideal product for your application.