Bearing and gearbox protection, new split seal designed for worn shafts and large runout applications.

Matrix: patented split rotary seal is easy to install, minimizes downtime and eliminates costly repairs and leaks.

A.W. Chesterton is pleased to announce the market launch of the Matrix Rotary Seal.

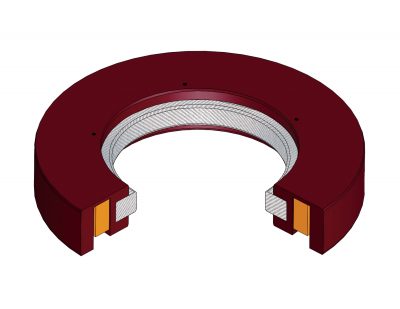

The patented Chesterton® Matrix Rotating Seal is a split seal designed for bearing protection. It has been developed to work on worn equipment that may have significant run-outs. The unified design is an innovation. It combines two of Chesterton’s proprietary technologies, polyurethane and impregnated synthetic fibres, to optimise the performance and reliability of the Matrix seal.

Features:

- Quick and easy to set up

- Made to measure

- Designed for a wide range of shafts from 50 to 762 mm diameter

- Suitable for shafts with worn surfaces

- Supports runouts up to 1.5 mm

- Rotation speed up to 15 m/s

The MATRIX rotary seal can be used in virtually all industries and in particular for large equipment such as pumps, gearboxes, conveyors, motors, fans and bearings. It provides effective protection against external contamination and maintains optimum lubrication inside bearing housings by eliminating leakage. With its patented split design, installation can be reduced from hours to minutes, avoiding costly disassembly, reassembly and labour.

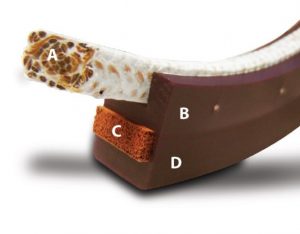

Joint Matrix: Construction

The braid (A), made of impregnated synthetic fibre, creates a seal against the rotating shaft. The nylon pins (B) prevent the seal from rotating with the shaft. Closed cell foam (C) energises the braid and helps create a good seal. The cage (D), made of flexible and durable polymer material, unifies the assembly and energizes the seal.