Chesterton is a full-solutions provider for pulp and paper mills and understands energy, efficiency, reduced water consumption and downtime are key cost differentiators in the industry.

The pulp and paper industry faces several significant challenges today. These challenges span environmental, economic, technological, and regulatory aspects. Some of the main challenges are the aging infrastructure, cost of energy and maintenance as well as water scarcity and environmental regulations.

Mechanical seal technology plays a vital role to combat challenges in Today’s environment for the manufacturers in Pulp and Paper Industry.

Keep your Machinery Running 24/7 – Achieve More Reliable Sealing of your rotating equipment

Chesterton’s advanced mechanical seal technology utilizes high-quality materials that provide long-term resistance to corrosion from chemicals such as caustic soda and chlorine compounds, as well as erosion and wear from abrasive particles in the pulp slurry.

Our mechanical seal designs are ideal in applications with varying pressures, temperatures and speeds / flow rates and are easy to install, inspect and replace. Maintenance times and costs can be significantly reduced, resulting in optimum operating efficiency.

Chesterton cartridge seals reliably minimize leaks and maximize pump performance

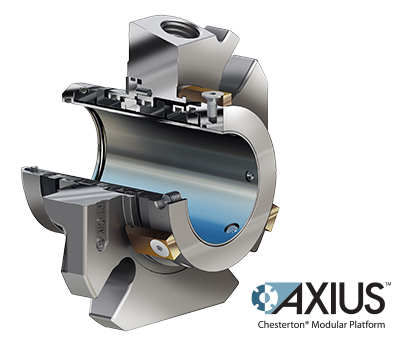

Chesterton offers a wide range of suitable mechanical seals for the demanding paper industry. In this article, we like to highlight our AXIUS™ Platform 1510 Single Cartridge Seal. With this pre-assembled cartridge seal, you can achieve maximum pump performance with simple installation:

- Reliable through temperature cycling and intermittent process with monolithic seal faces

- In service impeller adjustment is possible with the unique centering strap

- Mounts easily on various types of rotating equipment using Chesterton T.A.B.S.™ technology

- Prevents damage to your equipment and internal components via true non-fretting design

The Chesterton T.A.B.S. (Tapered Adjustable Bolting System) is an innovative fastening system that helps ensure even stress dispersion and optimum sealing due to its tapered design and adjustability. It offers numerous benefits, including improved sealing performance, longer component life, ease of installation and maintenance, increased operational reliability and cost efficiency. Due to these features, the T.A.B.S. system is successfully used in various industries, including the pulp and paper, chemical, power plant, and food and beverage industries.

Key Benefits of Chesterton Mechanical Seals

1. Plant wide standardizations with AXIUS Platform seals 1510 and 2510: Equipment standardization in industrial plants, including those in the pulp and paper industry, can significantly impact cost reductions in several ways.

Here are the primary benefits:

- Improved Reliability and Performance

- Lower Maintenance and Repair Costs

- Training and Workforce Efficiency

- Innovation and Upgrades

By adopting equipment standardization, plants can achieve significant cost savings across various areas, enhancing overall operational efficiency and financial performance.

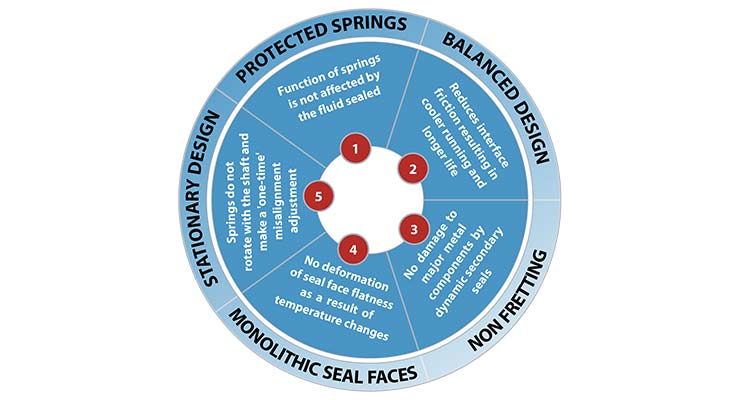

2. AXIUS Seal product line with 5 Key Seal features to “safety-belt” off conditions: These design elements help ensure that the seals can withstand challenging operational environments, reduce maintenance costs, and enhance overall equipment performance.

- Protected springs

- Balanced design

- Non fretting

- Monolithic seal faces

- Stationary design

By focusing on the five key features of mechanical seal design, Chesterton mechanical seals aim to provide high reliability, ease of use, and longevity in a wide range of industrial applications.

3. Improved Efficiency reduces overall cost: High-quality sealing technologies are crucial for the efficiency of pulp and paper systems. Water and energy savings are critical for reducing environmental impact and operational costs. Here is how they contribute to these savings:

- Energy savings through reduced friction losses compared to gland packing technology.

- Water savings by eliminating or reducing seal leakage and flush requirements.

Decades of presence in the paper sector bring plant operators forward

Chesterton has been a leading supplier of sealing solutions in the paper industry for many years. Our advanced mechanical seal technology effectively contributes to a longer service life of mechanical equipment, significantly extending MTBR. Chesterton also has systems that achieve considerable savings in flushing water.

With the Chesterton Connect™ system, we also offer an IIOT-based monitoring solution for mechanical seals and rotating machinery that monitors the performance of your equipment and alerts you to anomalies that could lead to downtime or malfunctions.

For more information about our mechanical seals, visit our “Reliability Matters” blog, which covers essential topics such as the “5 Key Features for Good Mechanical Seal Design.”

Here you can gain an insight into our decades of experience in the water and wastewater sector:

Case Study #1:

Chesterton 1510 Seal and Connect Monitoring Increase MTBR

Case Study #2:

Chesterton 442C Cartridge Split Seal & SpiralTrac Saves Plant 3 Million Gallons of Water

Pulp and Paper Brochure:

Pulp and Paper Brochure – Industry Solutions and Services

Conclusion

Addressing the challenges the pulp and paper industry is challenged with multiple requirements a multifaceted approach, including adopting sustainable practices, investing in new technologies, improving operational efficiency, and engaging with stakeholders to align on environmental and economic goals.

A thorough review of equipment and their sealing solutions in terms of water and energy efficiency is required and Chesterton solutions are available to increase plant profitability in many ways.

Do you have any questions about our Mechanical Seal Technology? Our Expert Desk is here to help. We are happy to assist you!

You can also make a preliminary selection using our product selector. Our product consultants will gladly assist you in selecting the ideal product for your application.