-368x400.png)

Simple Installation and Increased Reliability Plant-wide in General Duty Applications

Chesterton, a global leader in equipment sealing and reliability, has released its newest mechanical seal product – The 1510 General Duty Single Cartridge Seal.

Accompanying the recently released 1810/2810 high performance seals, this seal represents another foundational component for Chesterton’s cartridge seal portfolio and future mechanical

seal business.

Simplicity & Reliability

The 1510 continues to build on the philosophy of Chesterton. The way we think, design, manufacture, and deliver our products to our users is about value, response time, and quality.

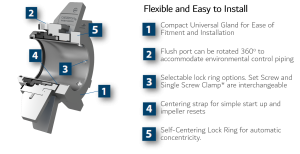

Designed with a compact cartridge profile and utilizing the Chesterton T.A.B.S (Tapered Adjustable Bolting System) field proven on the 155 and 442 split seals, the 1510 is designed to fit and install

easily on process equipment throughout industry. The unique resettable centering strap allows for impeller adjustments even after the seal has been fitted. Incorporating Chesterton’s 5 key features

of good mechanical seal design, the 1510 sets the new standard for general duty cartridge seals.

1510 Single Cartridge Seal – Reliability Made Easy

Advantages

- Reliable through temperature

cycling and intermittent process

with monolithic seal faces - In service impeller adjustment

is possible with the unique

centering strap - Mounts easily on various types

of rotating equipment using

Chesterton T.A.B.S. - Prevents damage to your

equipment and internal

components via true

non-fretting design