Hydro turbine shafts are sealed using various sealing methods. One of the traditional methods of sealing turbine main shafts is compression packing. Compression packing has several advantages over alternative sealing methods:

– Relatively simple technology

– Non-catastrophic failure

– Low initial cost

Many hydro turbines in operation today are still sealed with compression packing, besides the other technologies that are available and used. Unfortunately, compression packing has some disadvantages as well:

– Maintenance intensive – retightening and frequent replacement

– Leakage – compression packings are generally not hermetically sealed and, on a rotating shaft, require some leakage for lubrication and cooling.

Packings can be replaced by other methods, but this can be costly and sometimes technically infeasible. A.W. Chesterton Co. has developed technology to overcome the disadvantages of packing. This technology reduces maintenance, extends MTBR and reduces downtime and costs.

1. Compression packing technology

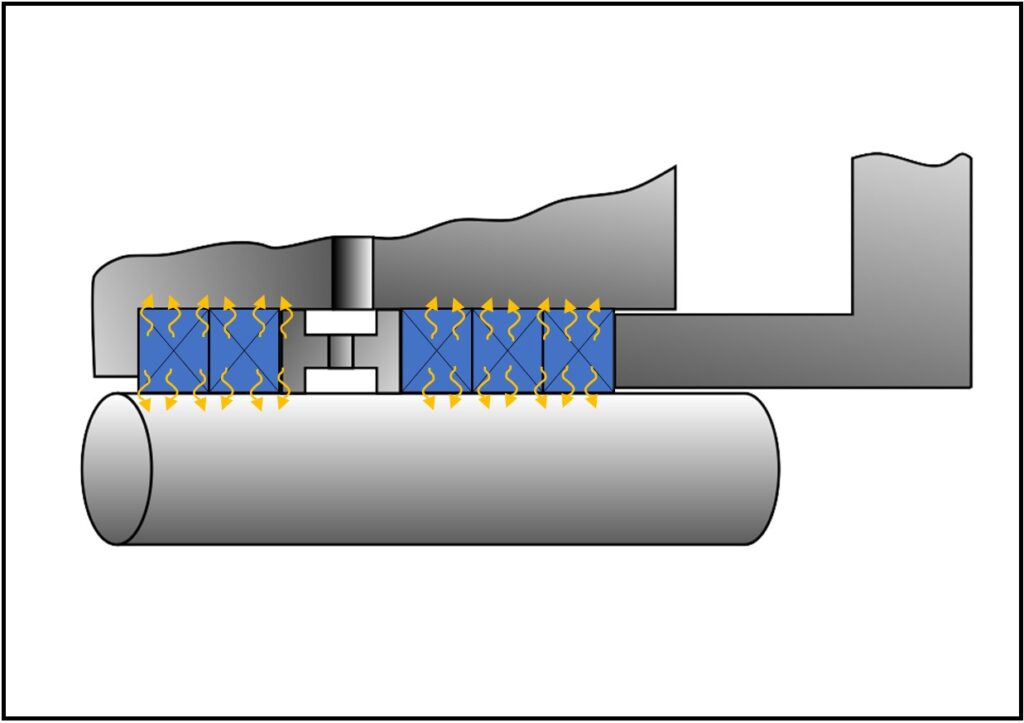

Let us take a look at the technology behind compression packing. Compression packings are braided from synthetic or natural fibres and they are filled with lubricants and blocking agents. These lubricants are usually mineral or synthetic oils or greases. PTFE suspension is also a commonly used lubricant. Lubricants have a dual function. They reduce friction between the shaft and packing, but also act as a blocking agents to prevent water from seeping through the packing braid structure. Packing rings are installed in a cylindrical shaped chamber called a stuffing box (figure 1).

Typically 4-6 rings of packing are installed in the stuffing box. The gland follower on this stuffing box is used to compress the packing rings. This follower creates an axial force on the packing rings which is converted into a radial force in the packing rings. This radial force is the force that creates the seal. Because lubricants slowly disappear from the packing (because they are squeezed out) and because the packing rings are subject to wear, the gland follower must be retightened from time to time. The frequency of this retightening requirement will vary depending on the application. It can vary from daily to monthly. Therefore, compression packing is by nature a maintenance intensive sealing method. Eventually, the lubricant will be used up and the packing will be worn to the point where it needs to be replaced.

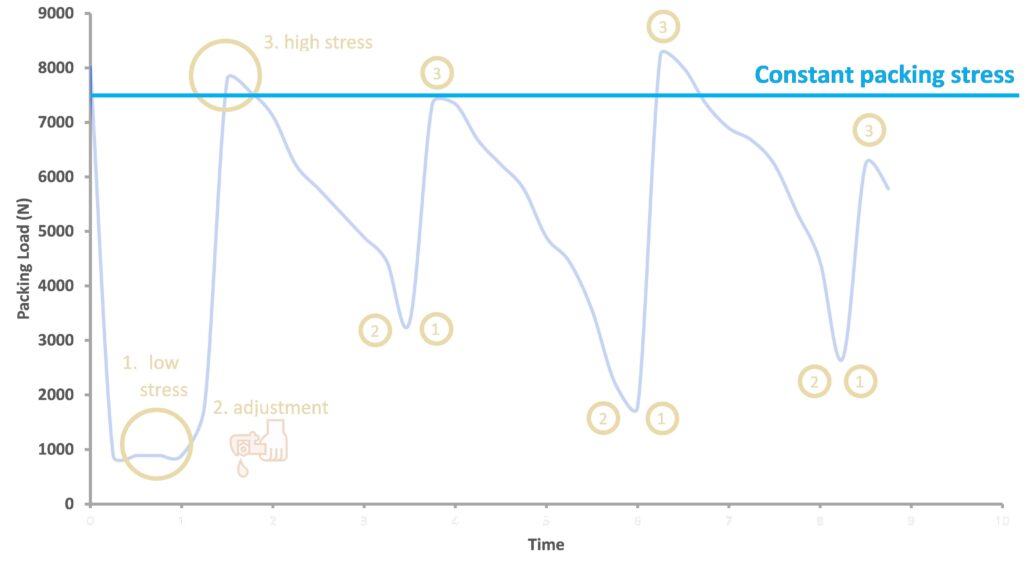

If we plot this retightening process on a graph and look at the packing stress versus time, we get the following graph (figure 2).

This maintenance cycle illustrates a number of issues associated with the use of compression packing:

- At the points where packing stress is low, solids in the sealed liquid can penetrate between the packing and the rotating shaft, wearing both the shaft and the seal, therefore further reducing packing life and potentially causing equipment damage.

- Frequent adjustments make the use of compression packing labour intensive

- The sealing stress is high at the peak of the maintenance cycle. Maintenance personnel tend to over-tighten the packing in an attempt to extend the time between adjustments. Unfortunately, this has the opposite effect because the packing suffers of additional wear and more lubricant is squeezed out. Therefore this shortens the life of the packing even further.

It would be more beneficial to maintain a constant moderate load on the packing. This would eliminate or reduce all of the above problems (figure 3).

2. Chesterton offers the optimum solution

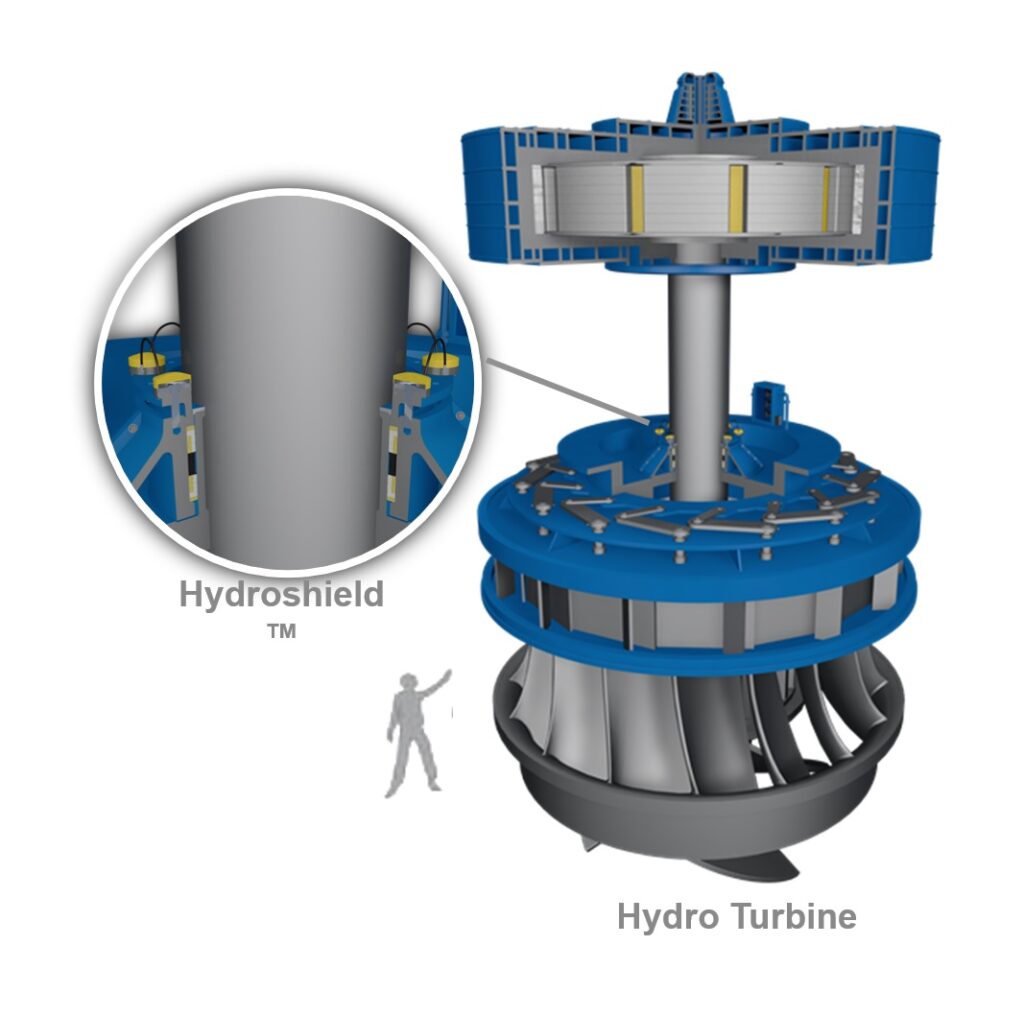

A.W. Chesterton Co. has developed a patented technology that eliminates the problems normally associated with compression packing. This technology is the Hydroshield™ system featuring Chesterton’s AMPS™ technology (Automated Mechanical Packing System).

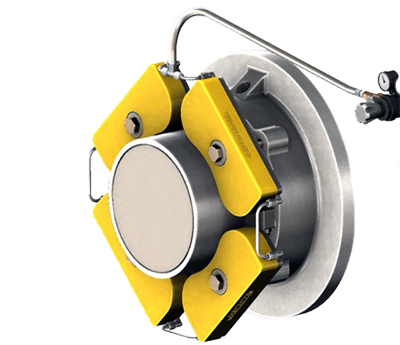

Hydroshield™ consists of pneumatic actuators located on the packing gland that maintain a constant force on the packing to keep the leakage level constant. As the packing loses lubricant and volume through wear, the system automatically adjusts. The system consists of several components:

– The compression packing

– The pneumatic actuators

– The interconnecting pipework

– A control unit

Figure 4: Chesterton Hydroshield TM system

The gas pressure is supplied by plant air or a gas cylinder. The control unit consists of at least a pressure regulator, but may optionally include a buffer tank to protect against loss of plant air pressure, and other auxiliary equipment to monitor and guard air pressure. The actuators are specifically designed to provide the force required to seal the packing in the specific stuffing box configuration. The pressure regulator is used to fine tune the pressure and keep the leak rate at an acceptable level. The air consumption of the system is very low. Typically 15 litres of air is used during the installation and initial adjustment of the packing and system. During normal operation the air consumption is close to zero. The gas pressure is only used to maintain a force on the packing.

The system is constructed from 316SS with Viton O-rings and a polypropylene dust cap. Materials can be modified to suit application requirements.

2.1 Technology comparison

Alternative technologies can be used to seal turbine shafts effectively. Radial Segmented seals and Mechanical Seals are alternative technologies that are successfully applied. The table below shows a comparison between technologies.

| Hydroshield™ | Radial Segmented Seals | Mechanical Seals | |

| Size | No limit | Up to 2000mm (80”) | Typically 760 mm (30”), Split seal up to 915 mm (36”) |

| Price | Most economical (when upgrading from compression packing) | Expensive | Most expensive |

| Pressure rating | Up to 35 bar (500 psig) | Around 10 bar | Up to 7 bar |

| Adaptability | Adjusts to system pressure changes | None | None |

| Flush condition | No special filtration system required | Special water Filtration | Maximal particle size 30-50 micron |

| Water usage | 0.02 L/Min Achievable | 20 – 90 l/min | Dependent on equipment |

| Smart Control | Remote control and monitoring (Connect) add-ons available | None | None |

| Installation | Easiest to install | Difficult | Difficult |

2.2 Sucessful Case history with Chesterton Hydroshield™

An example of an application is the refurbishment of a 100 year old Dominion Engineering turbine in Canada. The turbine shaft was sealed with compression packing and it was not possible to upgrade the system to an alternative sealing method. Bryson Generating Station is a run-of-river facility located on the Ottawa River. The Bryson station is owned by Hydro-Québec. Commissioned in 1924, it has a capacity of 61 MW with 3 units.

The major problem with the compression packing was that the area where the packing gland was located was subject to flooding and it was unsafe to retighten the packing gland while the turbine was in operation. The existing packing sealing system was weak and leaking heavily, causing unnecessary stoppages for maintenance. As a result, the turbine had to be stopped to retighten the packing. This resulted in costly shutdowns. The alternative was significant leakage over an extended period of time. The turbine shaft was 29″ (737mm) in diameter.

A Hydroshield™ system was installed on the packing gland in combination with 5 rings of DualPac 2212 compression packing. Hydro-Quebec certifies that the system meets the technical requirements. The system has been in operation since the beginning of 2021 and the packing is replaced preventively during regular outages. The customer has also upgraded the 2 other turbines with the same system.

3. Conclusion

Compression packing is a sealing method that is still widely used in hydro turbine shaft applications. While compression packing has some advantages, it also has some disadvantages. The main one is that compression packing on rotating shafts is maintenance intensive. Chesterton has developed a system that eliminates maintenance to a great extent on packed glands and extends the life of the packing. The system reduces the operating cost of the turbine, increases reliability, and increases worker safety. The system has been successfully installed in several turbine applications around the world.

Do you have a specific question? Please ask our Expert Desk.

You can also make a preliminary selection using our product selector. Our product consultants will gladly assist you in selecting the ideal product for your application.

The Author:

Hans E. Dekker graduated as a Bachelor of Engineering at the Saxion Polytechnic in Enschede in the Netherlands. He is working in the sealing industry for over 25 years in various functions in Engineering and Marketing. He is the Product Line Manager in Europe, Middle East and Africa for Compression Packing and Gaskets for the A.W. Chesterton Company. Hans is an active member of the European Sealing Association.