In thermal power plants, regardless of the type of fuel used, the need for high-purity demineralized water is essential. This water is critical for producing steam to drive turbines and generate electricity. A reliable supply of demineralized water helps ensure the efficient and safe operation of the plant, as it prevents scaling and corrosion in boilers and associated systems.

This boiler feed and make-up water is treated with various types of chemicals and demineralized to ensure it meets the needs of the boiler system for safe and efficient operation. This treated water is normally stored in large steel tanks before being used in the boiler system. It is imperative that the quality of the water does not deteriorate during storage. Therefore, these steel tanks are usually lined with a suitable material that not only prevents corrosion of the steel tank but also does not leach any unwanted substances into the water.

ARC SD4i demonstrates outstanding properties and beats competitor products in extensive test series

Chesterton offers qualified industrial coating products for a wide range of applications in fossil and nuclear power plants, helping our customers to improve productivity and efficiency. In this article, we focus on an outstanding major project – one of our impressive success stories:

“Back in 2007, a nuclear power plant in Europe was experiencing contamination issues of their ultra-high purity refueling water storage tanks due to deterioration of the rubber lining. Initially the power plant intended to replace the old rubber lining with a new one. However, unacceptable amounts of prohibited substances were discovered during leaching tests of the new rubber liner. Replacing the tanks with new stainless-steel tanks was considered but was deemed to be cost prohibitive.

The local Chesterton coating partner was contacted and discussed the possible use of a ceramic reinforced coating, ARC SD4i, that had been successfully used by a nuclear power plant in the US in their condensate water storage tanks for over 10 years. A visit to the US power plant was organized and key personnel from the European plant travelled to meet with their counterparts in the US to find out directly about the performance of the ARC coating in the ultra-high purity water storage tanks.

The power plant also began a series of tests including leaching tests with various different liners and coatings to ensure they met their needs in terms of maintaining water purity and corrosion protection of the tanks. The leaching tests were conducted at 60°C and ARC SD4i was the only coating that passed all the tests.

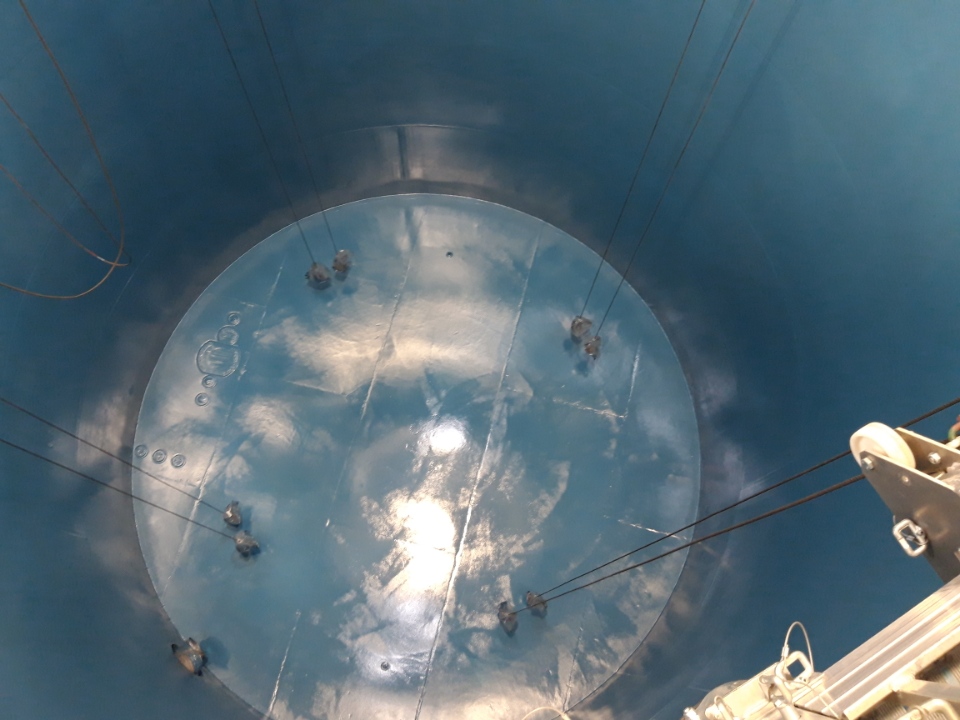

This started a project in 2017 to coat all of the safety classified rubber lined tanks with ARC SD4i. Each tank had to be emptied, the existing rubber liner removed, the steel surface prepared to specification and then, application of the ARC SD4i coating using a heated plural component airless sprayer.

All of this work had to be completed within a short outage window following strict quality and safety requirements. This challenge was successfully met by the applicator who was able to apply the ceramic reinforced coating on time and to the satisfaction of the power plant. Over the following five years another 10 water storage tanks were lined with ARC SD4i. During this time, the power plant has seen a vast improvement in the purity of the water coming from the ARC lined tanks.”

Reliable long-term performance leads to superior customer experience

It often takes many years before such large-scale projects can be successfully realized. Especially in a demanding business like the power industry, which only allows qualified coating products in accordance with special standards.

The 11 tanks in the project described above have been in operation for many years. Our customer is still very satisfied with ARC SD4i – the quality of the water is impeccable, no contamination, no signs of corrosion. It is worth mentioning that in each tank an area of 980m2 was coated in a short period of 11 days! As production downtimes are very expensive in the energy sector, only a very short time frame is specified for each type of maintenance work.

Conclusion

When it comes to protecting the quality of water used in thermal power plants, Chesterton ARC coatings have proven that they have the required properties needed to achieve long-term corrosion and water purity requirements.

If you would like more information about Coating solutions for your facility, please contact our Expert Desk.

You can also make a preliminary product selection using our product selector. Our product engineers will gladly assist you in selecting the ideal product for your application.