Interview with Volkert Wanner, Head of the production site in Germany, conducted by Vitaly Igonin, Marketing Coordinator for Europe, Middle East and Africa

Vitaly Igonin (VI): Hello Volkert, you invited us to come and see the new Mechanical Seals Production Centre in Ismaning near Munich. We would like to ask you some questions about this project,

First of all, what makes this project unique?

Volkert Wanner (VW): This is unique! We are working here on a project that, through its digitalisation and the technologies used, brings us into Industry 4.0

In 2019, Chesterton was launching new cartridge fittings on the market that are manufactured on the new AXIUS™ production platform. This modular platform has revolutionised the way we design and assemble GMs and enable our customers to reduce the lifecycle costs of their installation.

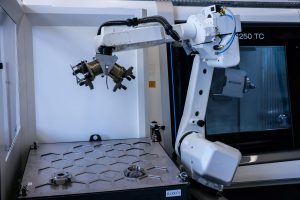

To make this possible, Chesterton decided to invest in new equipment and technology: We use a state-of-the-art DMG Mori CTX beta 1250 TC machining centre, to which we have integrated a 2nd generation Robo2Go. This innovative solution offers a flexible automation configuration and an intelligent safety concept for man-machine collaboration. These machines were installed both at our headquarters in Groveland (MA-USA) and here in Germany in Ismaning.

To support the production, other investments were necessary: the installation of a new vertical storage unit but also specific equipment such as laser marking and quality control including RFID technology for the traceability of our mechanical seals.

This project is global and innovative, which is why it is unique!

VI: T Where are we today and what is the production schedule?

VW: We are now in the scale-up and test phase, with a planned start date of 1 September 2020.

The production ramp-up will take a few months. Our priority is to mass-produce the standard sizes and, later on, to offer trim modifications to meet customer demands. These engineering solutions will be carried out by our design office here in Ismaning. In a year’s time, we plan to develop new products.

VI: What prompted the management in the US to come and invest here in Europe?

This was a strategic decision due to high demand from local customers. We need this European production to ensure fast delivery and to offer high quality products that meet local standards. Europe accounts for almost 70% of the world’s OEMs. Chesterton is a very flexible company; we want to offer technical solutions to our customers all over the world. The decision to produce in Europe was a logical one, but it took time to make it happen!

On what criteria was the Ismaning site chosen?

Ismaning is already a production centre, we have an experienced and efficient customer service. Our engineering team is fully integrated with the US team. For many years we have been a logistics hub for assembly and shipping of gaskets for EMEA. Ismaning is also a repair centre allowing us to provide a high quality service to our customers. I am very proud that Ismaning can develop new products for the EMEA market and offer customised solutions!

In the long term, what is your vision for the project?

As our CEO Andrew Chesterton has said, “[we] need to invest in people, tools and technology, which are essential for the growth of innovation and that automatically means providing high quality services at every stage of [our] customer engagement”.We expect an evolution from today’s fittings to modular solutions incorporating smart technology. We are living in an era of globalisation, so we need to provide a high quality product that meets the requirements of the local market as quickly as possible in every part of the world.

We are also looking to the future and investing in talent. Chesterton International GmbH collaborates with leading universities and innovative technology pilots in Munich and Stuttgart.

In conclusion, our goal is to provide innovative solutions using state-of-the-art manufacturing technology and by uniting the sources of talent and knowledge that are the wealth of Chesterton.

Thank you Volkert for this interview, we wish you and your team all the best for this new adventure!

Product Information:

Enrico Zini

EMEA Product Manager – Mechanical Seals

Phone: +39 349-6251.920

Email: enrico.zini@chesterton.com

Media contact:

Laurent Prunier-Duparge

EMEA Marketing Manager

Phone: +33 628 73 51 35

Email: laurent.prunier-duparge@chesterton.com