Discover the Key to Optimal Equipment Performance

Condition monitoring is essential for maintaining the reliability of rotating equipment. Chesterton, with its strong expertise in pumps and sealing devices, has developed a product portfolio for the Industrial Internet of Things (IIoT). This innovation stems from the need to monitor critical equipment continuously, identifying threats not easily detectable through visual inspection. By analyzing operational data, Chesterton enhances the Mean Time Between Repairs (MTBR) of rotating equipment, leading to informed maintenance decisions and optimal equipment performance.

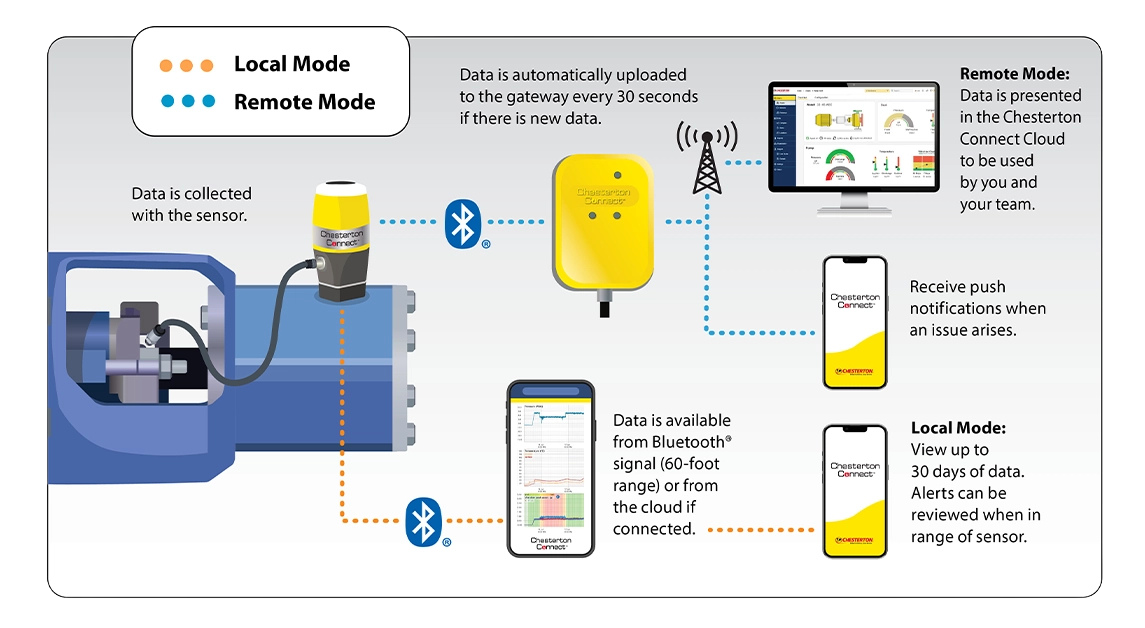

Chesterton Connect System

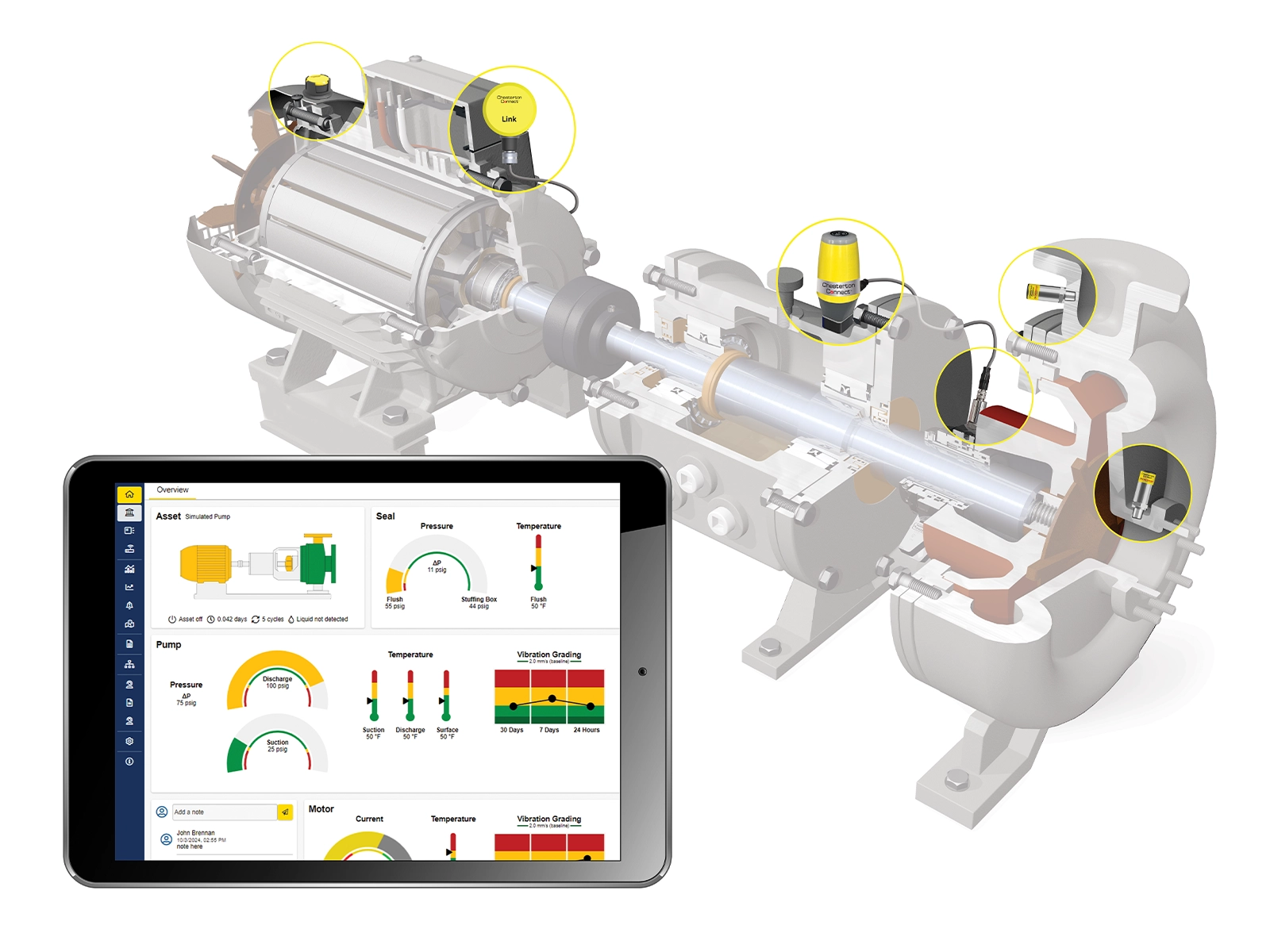

The Chesterton Connect System is an advanced 24/7 wireless smart monitoring sensor designed specifically for rotating equipment. It detects variations in:

- Process pressure and temperature: Monitoring these parameters helps identify restrictions in the suction, discharge, seal chamber, double seal piping plan, and shaft speed. This insight is crucial for understanding internal conditions and preventing seal failures.

- Vibration and surface temperature: Variations can indicate issues like cavitation, equipment misalignment, and impeller imbalance. This data helps technicians determine the optimal time for equipment assessment.

The Chesterton Connect sensor offers an easy-to-use, all-inclusive monitoring solution for all rotating equipment, enhancing reliability, safety, and performance. Installation takes less than two minutes, 24/7 data collection is seamless, and the user-friendly mobile app ensures straightforward data visualization and interpretation.

Integrating Pressure and Temperature for Enhanced Pump Monitoring

While traditional vibration monitoring is beneficial, integrating pressure and temperature measurements offers a more comprehensive view of equipment health. Changes in these parameters can indicate issues like seal failures or fluid blockages that vibration sensors might miss. Monitoring all three aspects ensures early detection of problems, enhancing overall equipment reliability.

Embracing the Future of Industrial Monitoring

Chesterton’s innovative approach to equipment monitoring represents a significant advancement in the field. Their comprehensive monitoring solutions offer complete visibility into equipment conditions, ensuring all plant operations run smoothly and efficiently.

Watch Laurent Prunier-Duparge Introduce the Chesterton Connect™

Join Laurent Prunier-Duparge, our IIoT Product Line Manager for EMEA, as he introduces the Chesterton Connect™ through a real-world application example. Learn how this revolutionary IoT sensor monitors critical parameters to optimize industrial equipment performance and reduce maintenance costs.

Watch the video below to learn more.

Want to Connect?

Contact a dedicated support for all your IIoT needs. Click here to get in touch with our expert team.

Chesterton Connect™ Solutions

Uncover our range of IIoT products designed for robust industrial performance.

Chesterton Connect™ – Wastewater Application

Discover real-world impacts of IIoT through our transformative success stories.

Vibration Condition Monitoring

Explore advanced vibration monitoring with Chesterton Connect™ for enhanced equipment reliability.

Monitoring in Hazardous Environments

Chesterton Connect™ IS: Certified for extreme ATEX and IECEx zones.

About The Chesterton Connect™System

Explore how Chesterton Connect™ enhances operational efficiency with IoT technology